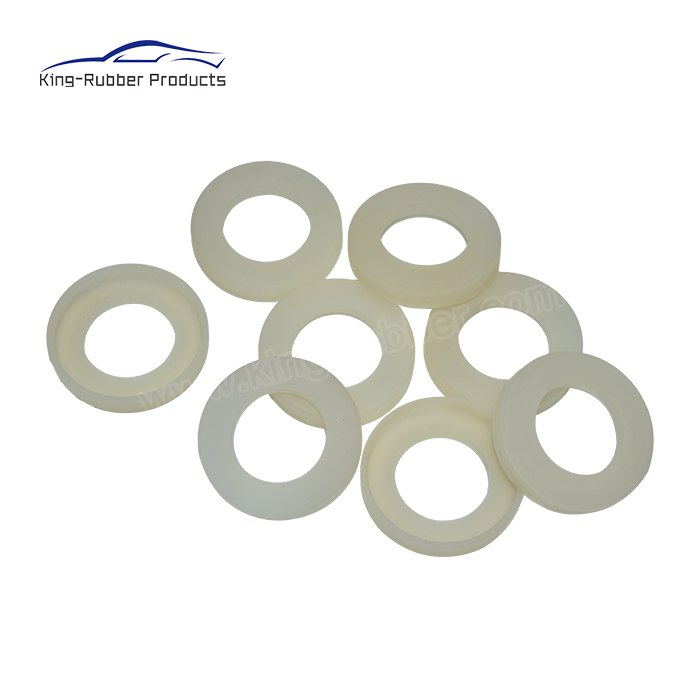

One of Hottest for Holder With Rubber Vibration Isolator - Rubber Parts , Custom Rubber Molding Products – King Rubber Detail:

Overview

Quick Details

| Product name: | Custom Rubber Molding Products | Color: | as your request |

| Hardness | 30-90 shore A or as your request | Model Number: | OEM |

| Files: | PPAP available | Certification: | ISO9001/TS16949 SGS FDA RoHS REACH |

| Material: | NBR,EPDM,FKM,Silicon rubber etc. are available. | Place of Origin: | China Ningbo |

| Processing Service: | Moulding | Advantage: | Aging resistance |

Supply Ability

| Supply Ability: | 500000 Piece/Pieces per Month |

Packaging & Delivery

| Packaging Details: | inner is plastic bag, outer is carton, or custom as per your requirement |

| Port: | Shanghai/Ningbo China |

| Lead Time : | Depending on the number of products |

1978-1982 Chevy Corvette C3 Fuel Gas Tank Filler Neck Gasket Boot Seal

Restoring any Corvette can be a daunting process and sometimes intimidating. One place to start can be with the 1978 through 1982 C3 Corvette fuel tank filler neck gasket boot seal to ensure that there are no breaks or leaks in your fuel system. This is the seal that mounts between the gas tank in the rear deck, and it is built to the exact specifications as the original. The quality is top-notch and the function is seamless.

| Item | Custom Rubber Molding Products |

| Material | NR, NBR, SBR, CR, EPDM, TPR, TPU, Silicone, ACM, FVMQ, FKM/VITON, FFKM, HNBR, PU etc. |

| Hardness | 30-90 shore A or as your request |

| Working temperature | ‘-70~250℃ or as your request |

| Size/Color | The size and color can be customized as per your drawings or samples. |

| Size Tolerance | as your request |

| Surface treatment | Polished or matte surface and can be stamped with logo etc. |

| Advantage | Oil resistance, UV resistance, Temperature resistance, Ozone proof, High tension resistance |

| Processing method | Compression, Extrusion, Injection, Silicone liquid injection |

| Production Capabilities | Wide ranges of machines including 100T, 150T, 200T, 250T, 300T, 400T and 800T |

| Certification | ISO9001, TS16949, FDA, RoHS, Reach (free samples for test can be offered) |

| Mold Life | 500,000 shots or 1,000,000 shots |

| Mold Cavity | Single-cavity or Multi-cavity |

| Mold fee | For customized parts we need to make mold for it and you have to pay for the mold fee. |

| The mold belongs to you and we will keep it well for next time use. | |

| Work Flow | Step1: Open a new mold according to your drawings or samples |

| Step2: Produce samples for your confirmation | |

| Step3: Arrange mass production after your approval | |

| Package | Inner OPP bag / outside carton / wooden pallets / wooden pallets / any other special package as your request |

| Delivery Time | Usually 1~3weeks depends on your quantity |

| Payment Terms | T/T, L/C, Western Union |

| Shipping | FEDEX, UPS, DHL, TNT, EMS, by air, by sea, by train, etc. |

| Port | Ningbo or Shanghai |

Rubber Parts , Custom Rubber Molding Products

We has solid design, precise machining,we are continuously developing new formulations to meet specific requirements from heat resistance to cold temperature resistance, chemical resistance, abrasion resistance and everything in between. Provide us with the details of your application and our experts will review your project, suggest an existing material or develop a new one and provide samples as needed.

• Accurate price caculate

• Better control on holding the part cost if raw material price increased

• Competitive price with stable quality

Custom design rubber gaskets, plugs, grommets, caps , screws, washers from direct factory pictures

Reasons for customers to choose King rubber:

1.Rubber, plastic expertise in the industry unparalleled

2.Large and varied tool inventory (35 years worth!)

3.Delivery times are often better than the industry average

4.Our expertise and experience combine in providing clients with superior choices.

5.You don’t use your computer or staff to tag your phone; You will work directly with experienced rubber consulting sales engineers.

6.We provide high quality customized rubber products, extruders and plastic products according to your requirements.

7.More than 99% deliver on time

8.Customer sample 2D, 3D production and proofing

9.PPAP IMDS ISIR SGS

10.Sample mold development (aluminum mold) reduces sample cost

11.Large warehouse stock

12.Professional mold development, testing and production

13.Lab sample test and material test follow-up

14.As an ISO 9001:2015 certified company, we have documented policies and procedures to ensure consistent quality and shipping.

15.Our packaging and retention programs minimize the frustration of reordering, managing productivity, and reduce your inventory operating costs.

Pre-sales

Solving problems and proposing sealing ways. Our engineers could offer design & selection support, and free sample could be provided for testing. King Rubber is solving sealing problems for global customers.

Middle-sales

To respect customers, service actively. Satisfying customers require-ments as our aim. Controlling product quality & delivery time strictly. 100% qualified.

After-sales

Tracking customers and replying questions positively. Answering problems patiently. If quality could not satisfy your request, return / exchange

policy is available.(Never happen until Now).

Inquiry Guide

In order to you can get faster and more accurate service, please send an inquiry according to this page

Enquiries parameters: size, material, hardness, color, tolerance, working environment, purchase quantity , etc.

1. Size:drawing or sample.

2. Material: NBR, EPDM, VITON, FKM, FFKM, NR, HNBR, CR, SBR,etc

3. Hardness: 30°~90°.

4. Color: according to your request, the most common color is black. The price of the white color products is litter higher than others.

5. Tolerance: if there is special size requirements, please mention in enquiries. Otherwise, we will be in accordance with the international standard tolerance execution.

6. Working environment: in order to produce more accurate production you need, please be sure to inform products work environment. Such as motion situation(is sports or stationary, whether there is friction), contact medium (exposure to corrosive gas, water vapor, acidic or alkaline liquid), etc.

7. Purchase quantity: please offer purchase quantity per month/year.

8. Customer information: in order to facilitate we understand more about your company, and contact you timely, please provide your company’s name, phone number, E-mail contacts.

If you clearly display above information,please send an inquiry to sales@king-rubber.com , we will reply to you as soon as possible! Thank you!

Product detail pictures:

Related Product Guide:

One of Hottest for Holder With Rubber Vibration Isolator - Rubber Parts , Custom Rubber Molding Products – King Rubber, The product will supply to all over the world, such as: , , ,