We persist with the principle of “quality 1st, assistance initially, continual improvement and innovation to meet the customers” for your management and “zero defect, zero complaints” as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for ODM Factory China Doors and Windows Rubber and Plastic Sound Insulation Sealing Strip, Our final target is “To consider the most effective, To be the Best”. Please experience cost-free to call with us if you have any prerequisites.

We persist with the principle of “quality 1st, assistance initially, continual improvement and innovation to meet the customers” for your management and “zero defect, zero complaints” as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for China Rubber and Plastic, Insulation, We set a strict quality control system. We’ve return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our goods. Be sure to feel free to contact us for further information if you have any questions. We have been glad to work for every client.

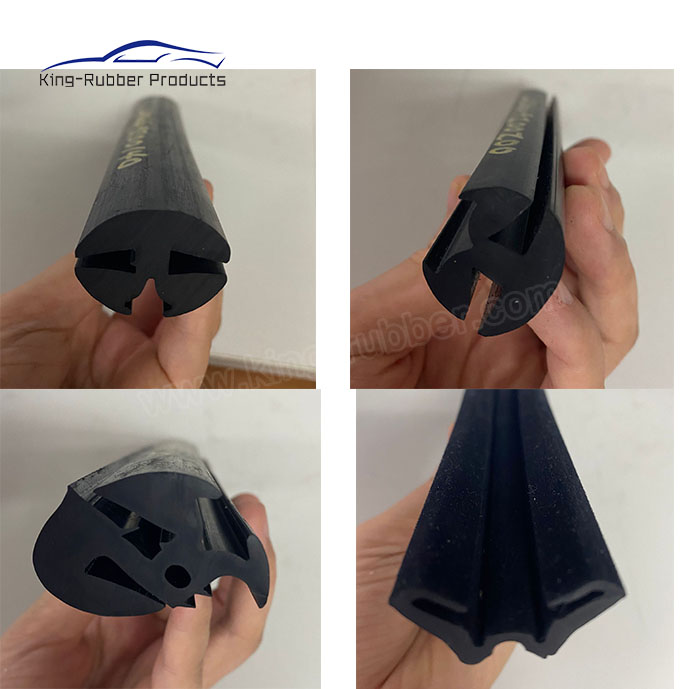

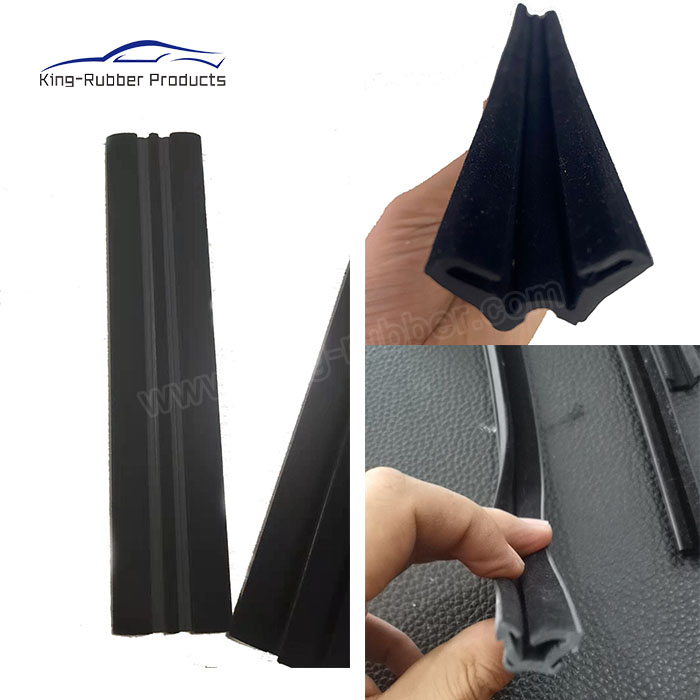

If you are looking for a company that handles rubber extrusions, look no further than King Rubber Manufacturing. We have experience working with a variety of materials across a number of different applications. Throughout every aspect of our business we keep our customers’ needs in mind, from the very first time we communicate to making sure the product reaches them. We understand that our business is dependent on customer satisfaction; this is why we work with you to provide a premium product that is custom made to fit your application better than a standard solution.

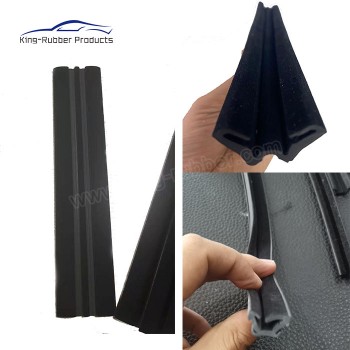

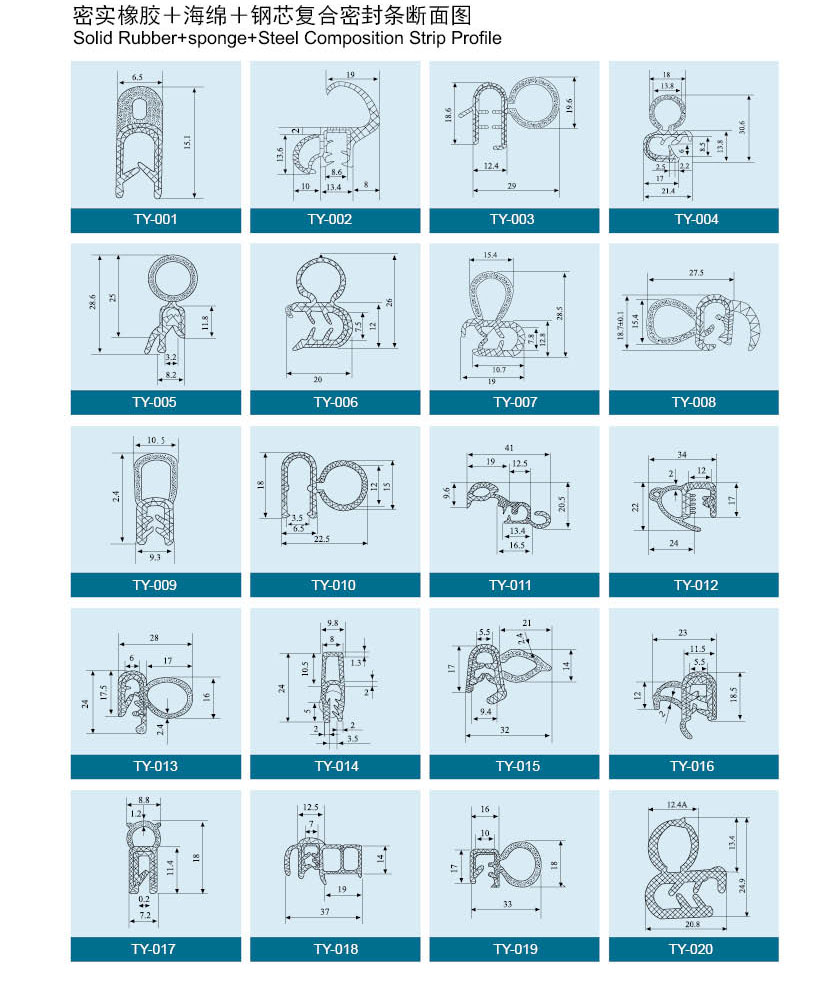

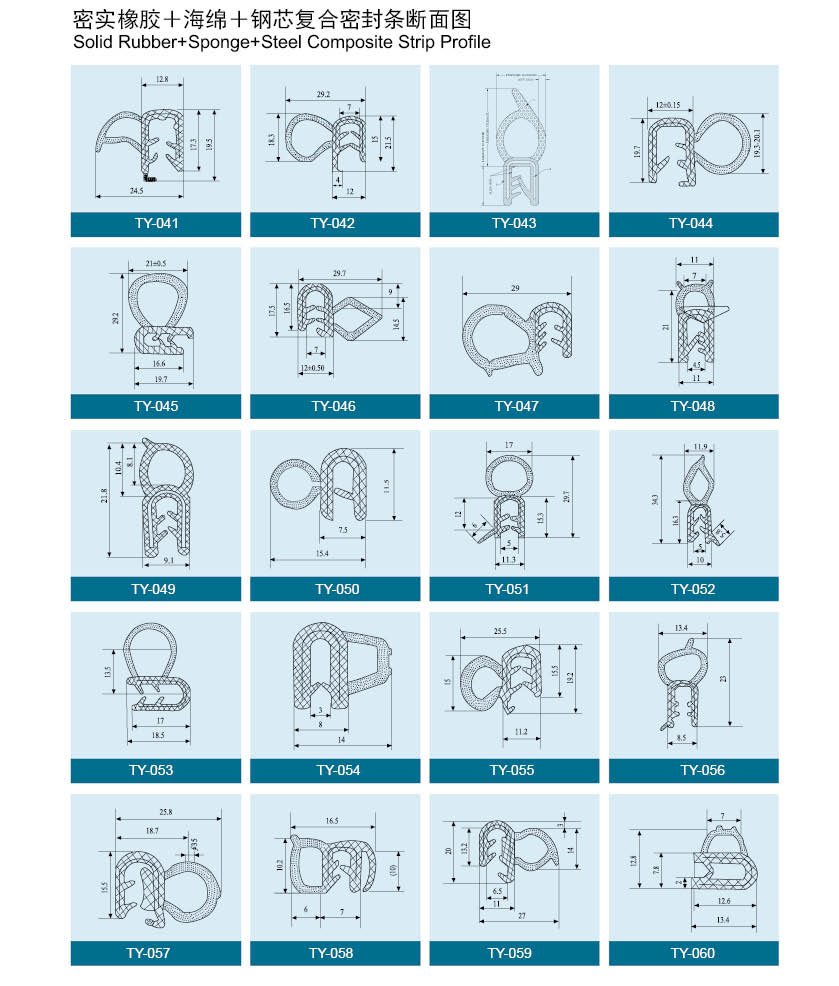

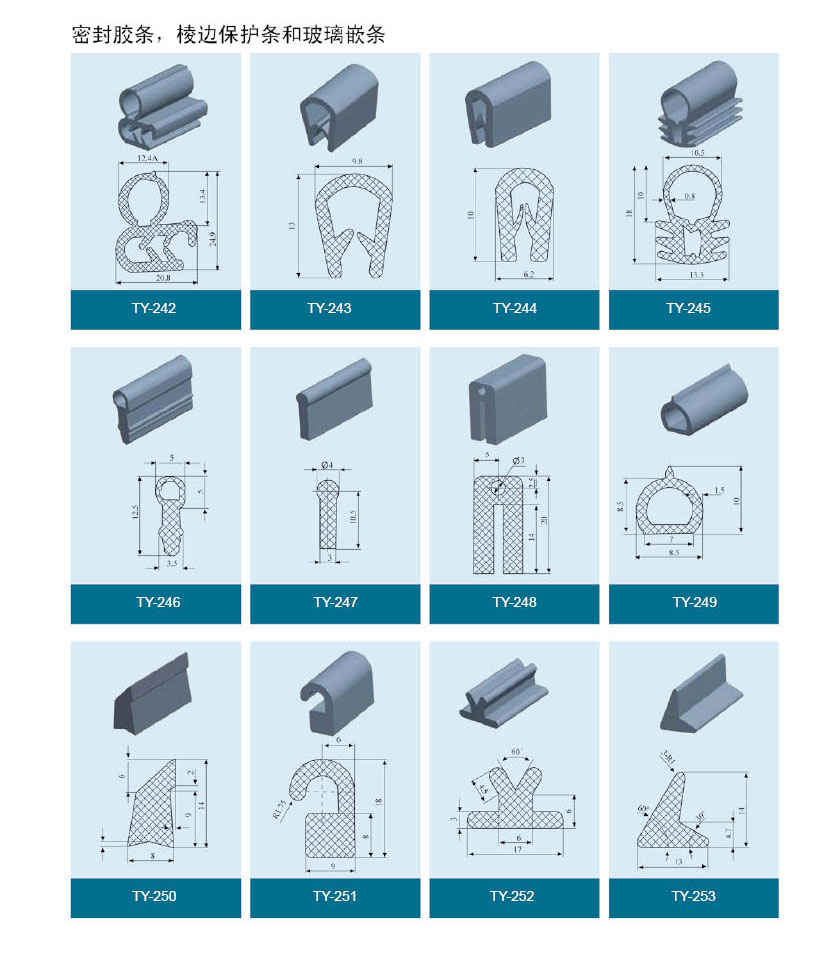

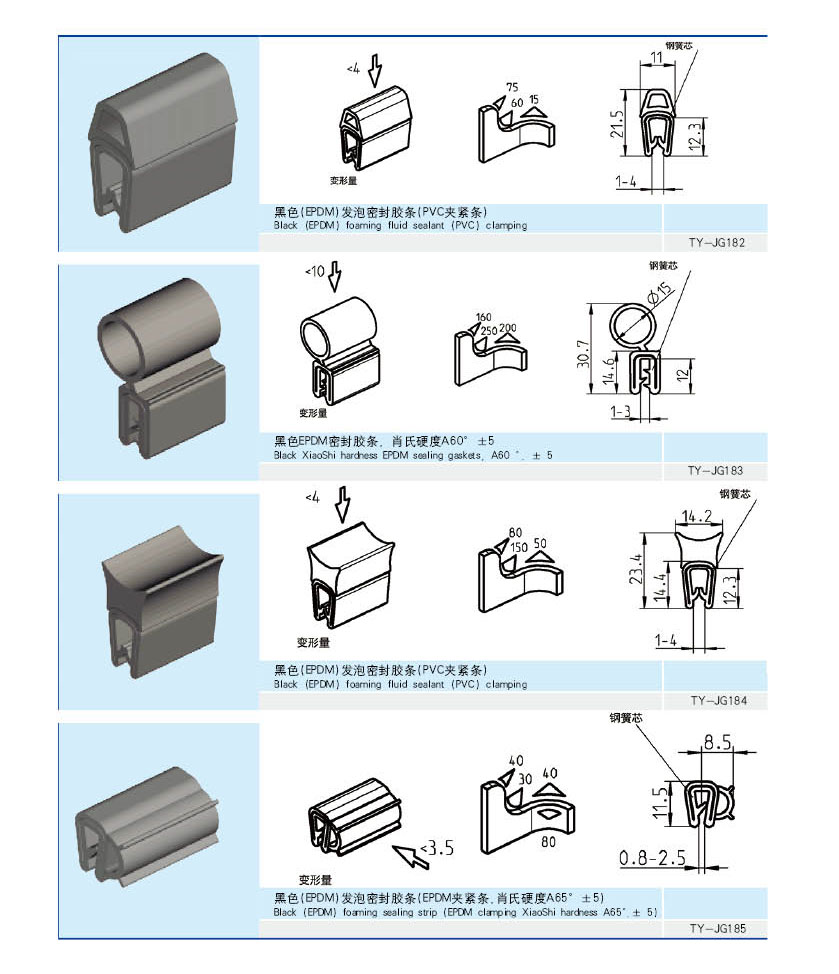

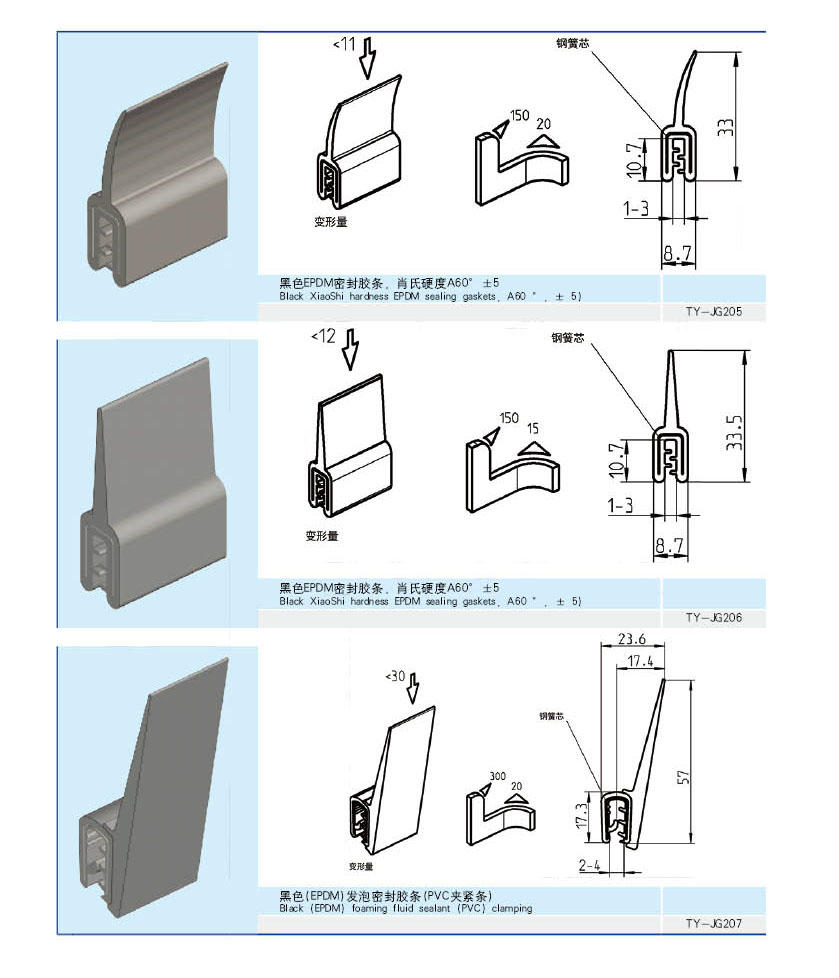

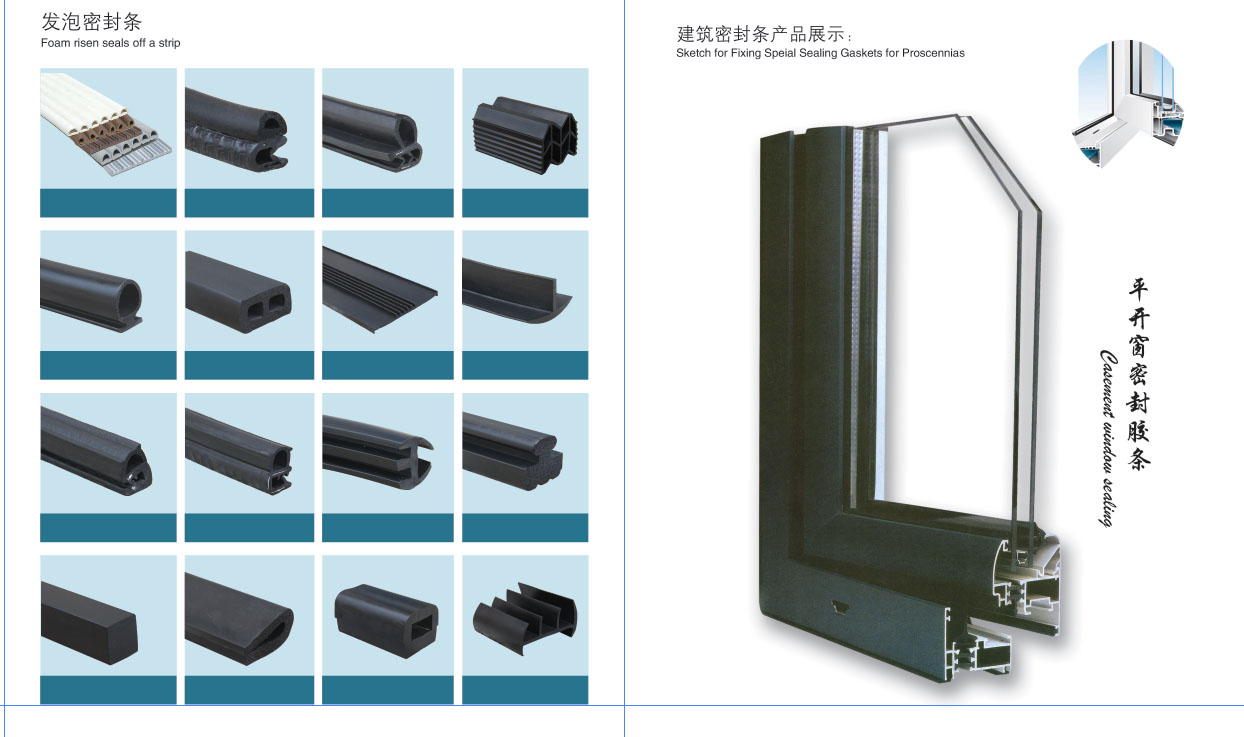

We understand that every application requires a unique product; this is why we offer a variety of non-metallic materials such as Neoprene, Viton, EPDM, Natural rubber, Nitrile, Silicone, SBR, and Urethane. We have plenty of experience working with a number of different applications and industries. Some of these industries include chemical, medical, automotive, aeronautical, marine, military, building, industrial, and many more. If you are in any of these industries or perhaps a different category, we would love to hear about your application and process so we can work with you to provide the best possible solution.

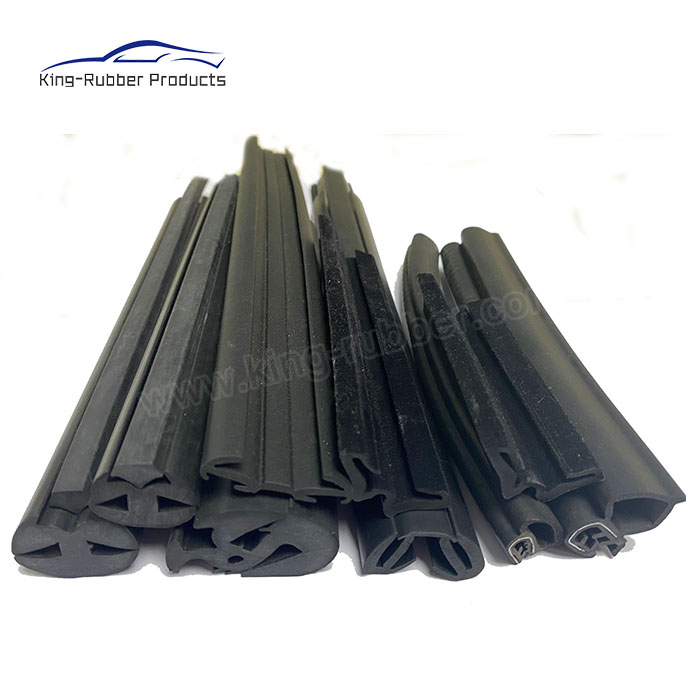

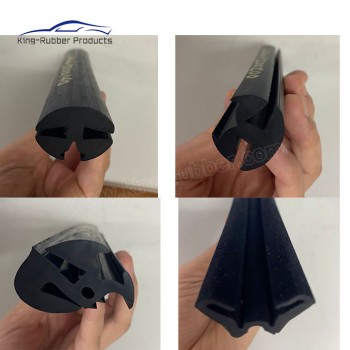

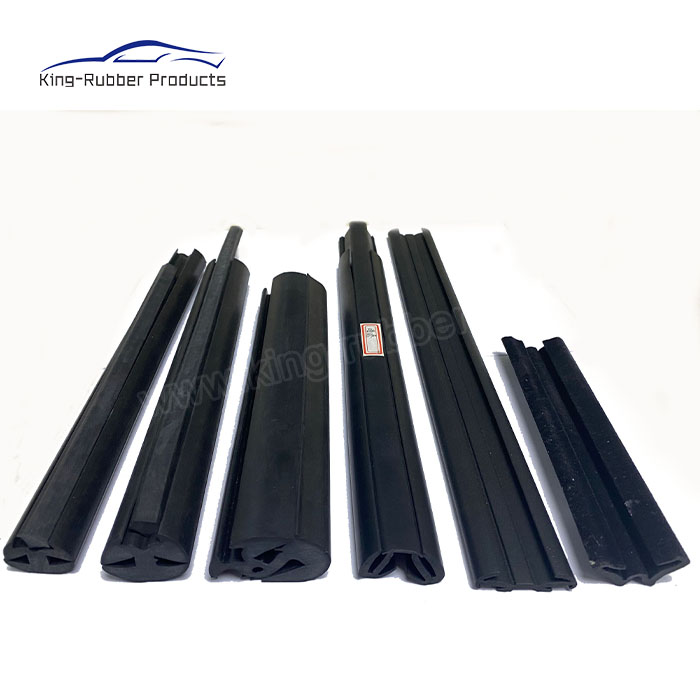

Rubber Extrusion

Many companies can offer rubber extrusions, but we actively seek the tough jobs. We are committed to holding critical tolerances, and delivering quality products. Our quality control assures that your products will meet or exceed your requirements.

OUR CAPABILITIES

Our state of the art machinery allows us to offer intricate profiles to 12″ in width. King Rubber has the following capabilities with rubber extrusions:

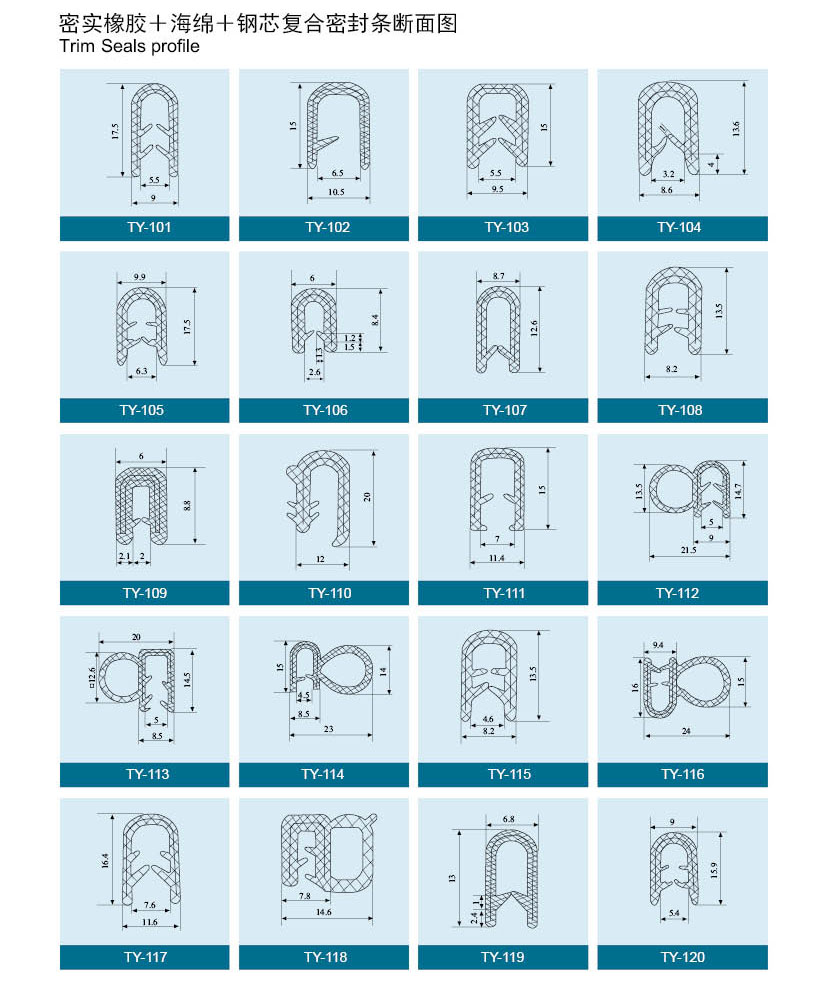

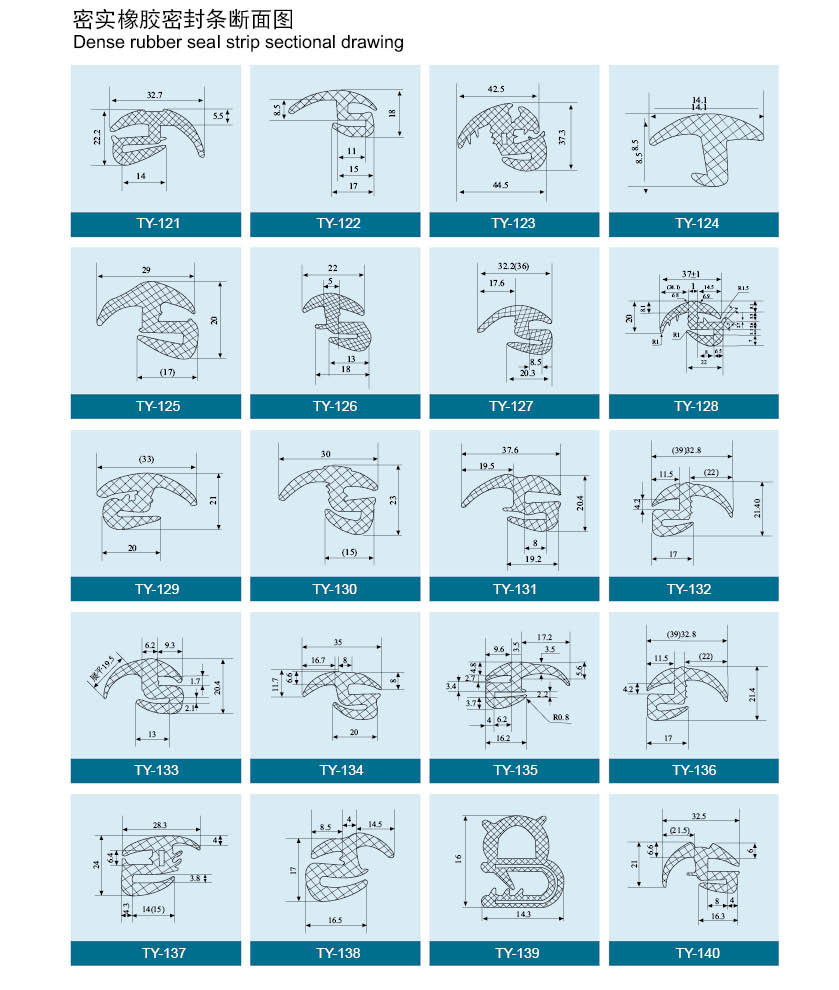

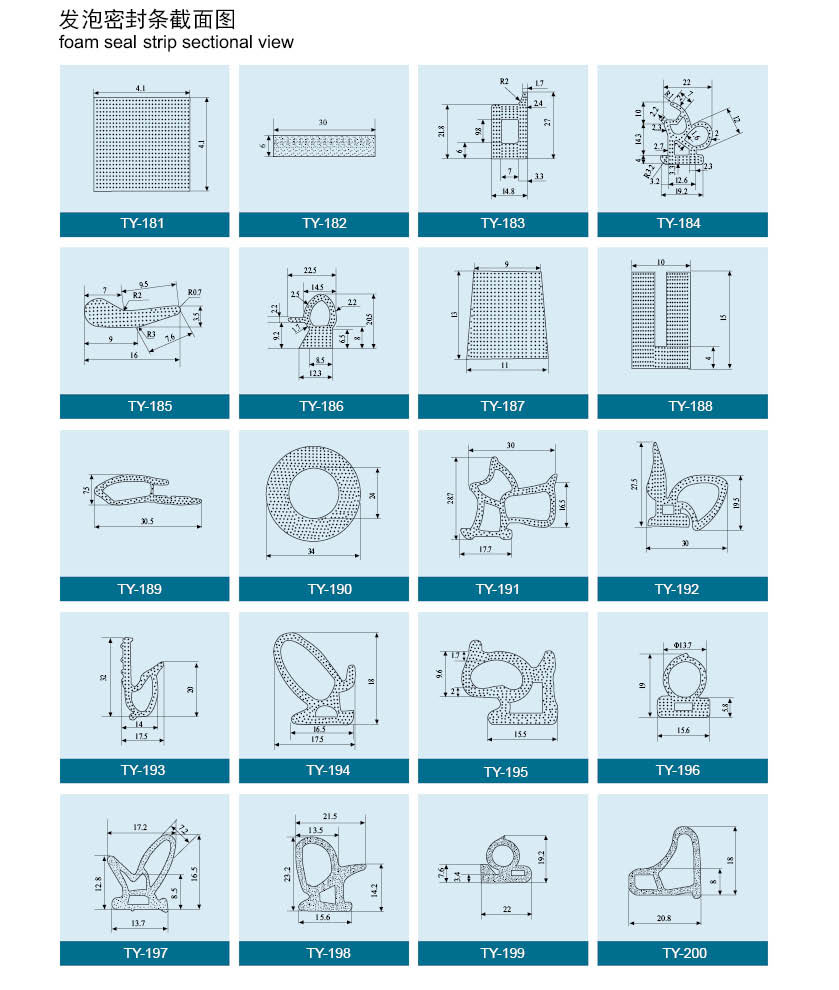

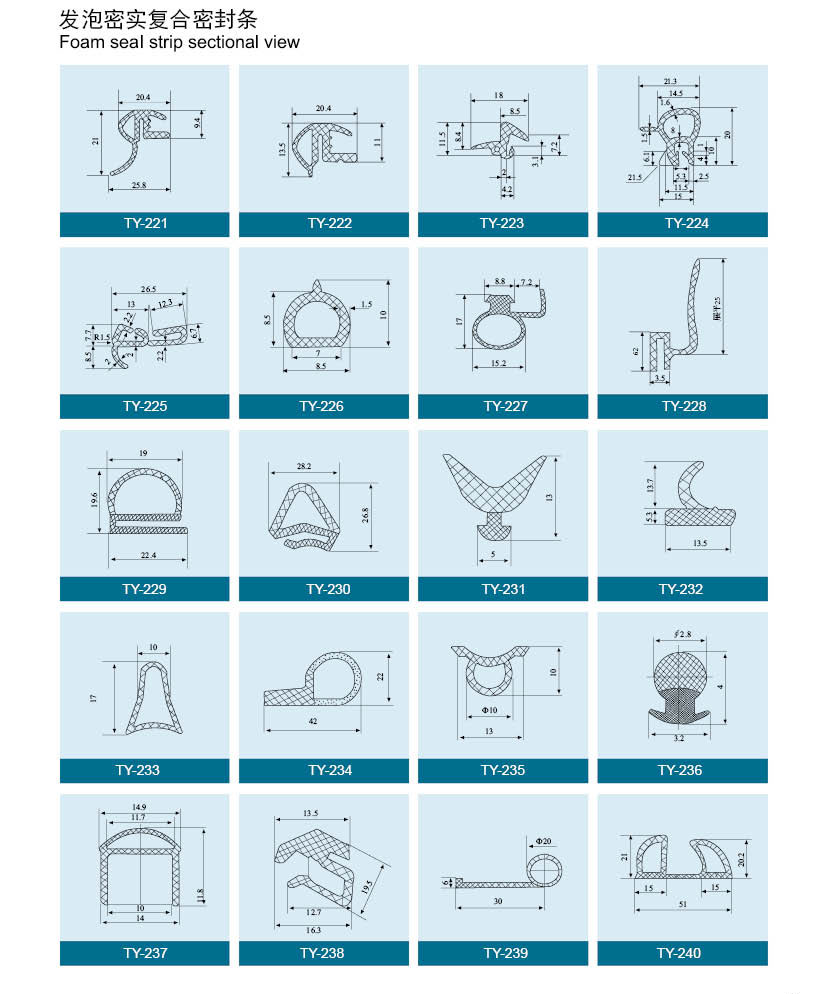

Dense and Sponge Materials

Dual Durometer

Microwave

Autoclave

Mandrel Cure

Cutting

Vulcanized Splice

Adhesive Tape

Miter Cuts

MATERIALS

Since 2001, King Rubber has been producing rubber parts from a variety of materials including:

- EPDM

- SBR

- Polyisoprene

- Polyurethane

- Natural Rubber

- Neoprene

- Buna N

- Nitrile

- Silicone

- Solid and Sponge

- Gum Rubber

Send your message to us:

-

Special Price for 260*85 3.00-4 pneumatic air r...

-

2019 New Style China Black NBR Pure Rubber Oil ...

-

High definition China Hot Sell Solid Extruded E...

-

Factory made hot-sale China Hydraulic Valves Dy...

-

Best Price on China Best Price HOWO Truck Engin...

-

High definition China Custom Silicone/NBR/EPDM ...