Leading Manufacturer for Hardened Steel Bushes - 30% Glass Filled Nylon Axle Spacer – King Rubber Detail:

Overview

Quick Details

| Product name: | Nylon Axle Spacer,Plastic parts | Color: | Any color |

| Hardness: | 30-95 shore A | Model Number: | OEM |

| Performance: | Corrosion | Certification: | ISO9001/TS16949 SGS FDA RoHS REACH |

| Material: | ABS, AS, PA, PE, PP PVC, PC, PE, Nylon, EPDM, POM, EPT^ | Place of Origin: | China Ningbo |

| Tolerance | 0.05mm | Processing Service: | Injection molding |

| Surface Treat: | Paint, texture | Temperature | -40°C to+300°C |

Supply Ability

| Supply Ability: | 1000000 Piece/Pieces per Week |

Packaging & Delivery

| Packaging Details: | inner is plastic bag, outer is carton, or custom as per your requirement |

| Port: | Shanghai/Ningbo China |

| Lead Time : | Depending on the number of products |

30% Glass Filled Nylon Axle Spacer

Feature

1.Ozone and Chemical resistance

2. Anti-aging, good flexibility, good elasticity

3. Excellent oil resistance

Application

Electronic field, industrial machine & equipment,house-hold appliance,tele-communication,automobile,medical equipment industry etc.

Fast delivery,high quality;

OEM,ODM welcomed;

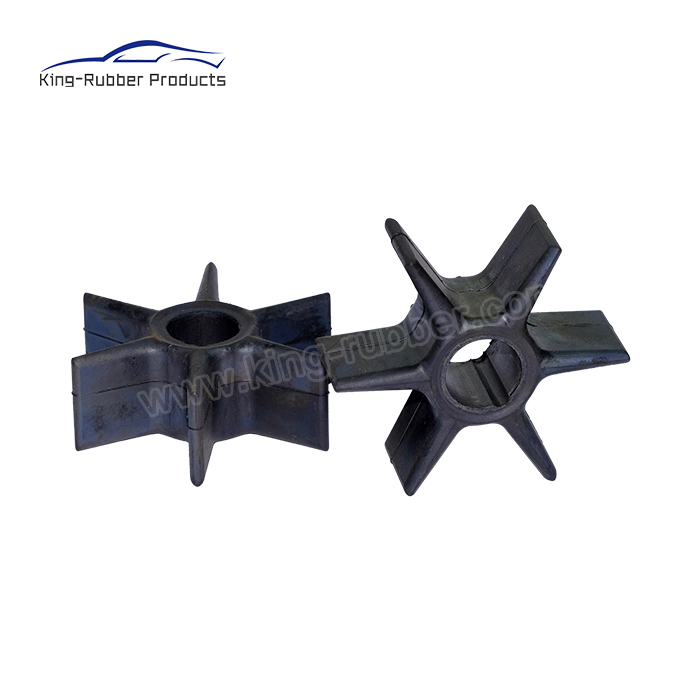

high quality plastic material of POM, PE, PA, PVC, PP etc., high mechanical strength, rigidity, fatigue resistance, resistance degeneration good shape. Excellent wear resistance, dimensional stability, creep resistance, good abrasion resistance, self-lubricated and frictionand dielectric properties, water resistance and solvent resistance. It’s an ideal replacement material for non-ferrous metal and alloy steel of copper, cast zinc, steel, aluminum and other metal materials. POM together with UHMWPE, PA, F4 are known as the four wear-resistant plastic materials. High thermal stability, good chemical stability and excellent electrical insulation. It is the first material choice for manufacturing gear. Apply to produce gears, springs, bearings, connecting rod, impeller blades, toys, windows, water tanks and washing basins of the industry in machinery, automobile, electronic and electrical.

high quality plastic material of POM, PE, PA, PVC, PP etc., high mechanical strength, rigidity, fatigue resistance, resistance degeneration good shape. Excellent wear resistance, dimensional stability, creep resistance, good abrasion resistance, self-lubricated and frictionand dielectric properties, water resistance and solvent resistance. It’s an ideal replacement material for non-ferrous metal and alloy steel of copper, cast zinc, steel, aluminum and other metal materials. POM together with UHMWPE, PA, F4 are known as the four wear-resistant plastic materials. High thermal stability, good chemical stability and excellent electrical insulation. It is the first material choice for manufacturing gear. Apply to produce gears, springs, bearings, connecting rod, impeller blades, toys, windows, water tanks and washing basins of the industry in machinery, automobile, electronic and electrical.

Specifications:

material: POM, PA, PE, PVC, PP etc.

color: white, black, blue

surface: smooth/smooth

tensile strength: 30-80Mpa

density: 1.2-1.5g/cm3

impact strength: 80-100KJ/m2moulding shrinkage: 2.5%-2.8%

resistivity: 1×10^14ohm.cm

cold temperature: -30°C

heat distortion temperature: +165°C

size: as per the buyer’s drawing or sample

quantity: 500pieces

Product detail pictures:

Related Product Guide:

Leading Manufacturer for Hardened Steel Bushes - 30% Glass Filled Nylon Axle Spacer – King Rubber, The product will supply to all over the world, such as: , , ,

Send your message to us:

Write your message here and send it to us

-

Super Purchasing for Rubber To Metal Bond Diaph...

-

OEM China Rubber Grommet Customized - RUBBER H...

-

Factory wholesale Injection Molding Machine - ...

-

Good Quality White Silicone O Ring - RUBBER EX...

-

Fixed Competitive Price Rubber Bearing Pad - O...

-

Competitive Price for Fire Resistant Rubber Gro...