With trusted good quality method, fantastic track record and perfect consumer service, the series of solutions produced by our enterprise are exported to lots of countries and regions for Bottom price China Custom High Precision CNC Machining Aluminium/Steel/ Titanium/Stainless Steel/Copper/Plastic CNC Turning Machining Parts, We have self-assured that we will supply the top quality solutions at resonable price tag, fantastic after-sales support for the customers. And we are going to develop a dazzling foreseeable future.

With trusted good quality method, fantastic track record and perfect consumer service, the series of solutions produced by our enterprise are exported to lots of countries and regions for China CNC Machining Aluminium Parts, CNC Turning Parts, Business philosophy: Take the customer as the Center, take the quality as the life, integrity, responsibility, focus, innovation.We will present experienced, quality in return for the trust of customers, with most major global suppliers?ê?all of our employees will work together and move forward together.

Overview

Quick Details

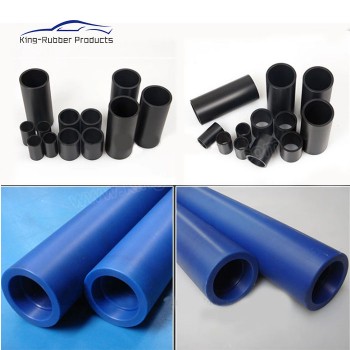

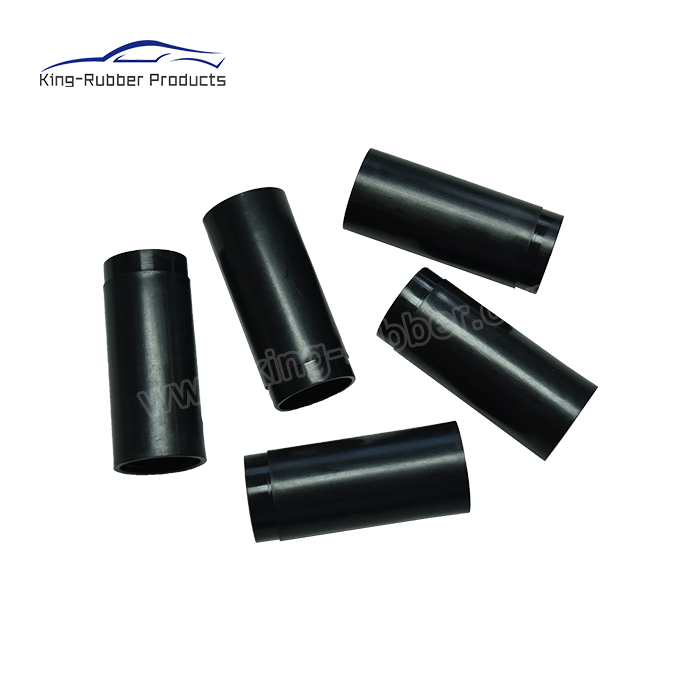

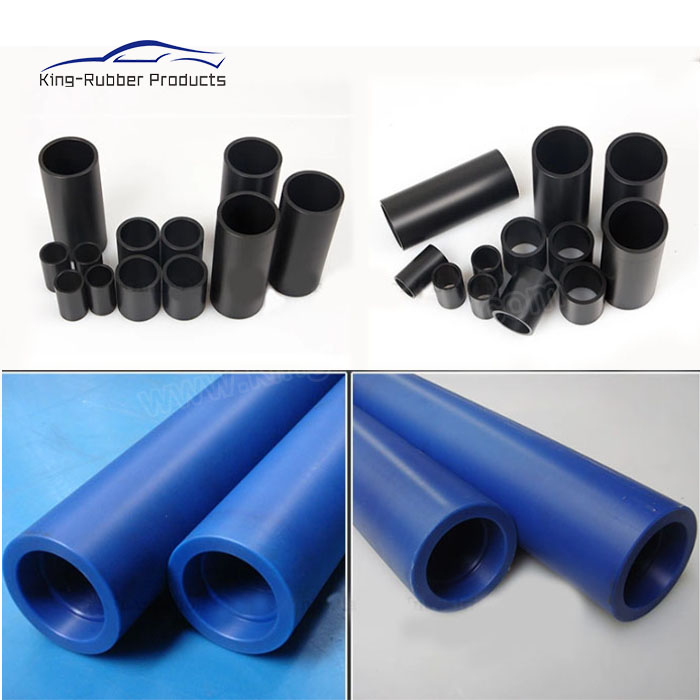

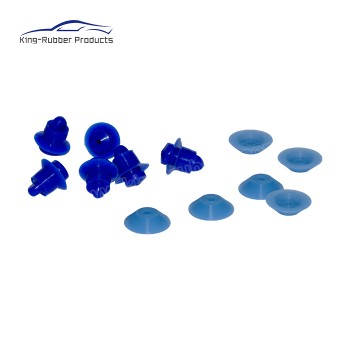

| Product name: | black tube plastic pipe | Color: | Any color |

| Hardness: | 30-95 shore A | Model Number: | OEM |

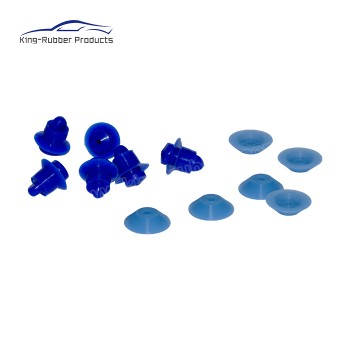

| Shape | Sheet, rod, tube, gear, rack,pulley, guide rail, Plastics fittings,and so on | Certification: | ISO9001/TS16949 SGS FDA RoHS REACH |

| Material: | POM,PVC,Nylon,PEEK,PU,PA,Acrylic,PE,UPE,PTFE,etc. | Place of Origin: | China Ningbo |

| Diameter | 5-200mm,or customized | Processing Service: | plastic injection |

Supply Ability

| Supply Ability: | 1000000 Piece/Pieces per Week |

Packaging & Delivery

| Packaging Details: | inner is plastic bag, outer is carton, or custom as per your requirement |

| Port: | Shanghai/Ningbo China |

| Lead Time : | Depending on the number of products |

Custom high lubrication black tube plastic pipe

We are a company specializing in making rubber & plastic & metal material customized parts according to your samples or drawings ,and many kinds of Custom made Plastic parts we can provide .

Plastic-injection molding is the preferred process for manufacturing plastic parts, as it is ideal for producing high volumes of low-cost plastic parts with high tolerance precision, repeatability and little to no finishing required.

King-rubber began OEM & ODM Rubber & Plastic since 1991.

Our company has a professional, complete production equipment, Injection Machines total 80 sets, from 80T to 1200T. With high precision and top quality.

We have our own mould making production line, it’s better for us to control the quality, and improve our effective to shorten the production time. Our mould life can meet oven 1,000,000 shots.p

If you need Rapid Prototypes to test the part structure before mould investing, we also can help you. We have our own production line for prototyping, Prototypes Material can be ABS, POM, PP, PC, PE, PA(Nylon), PA+GF, PVC, PBT, ABS+PC, etc.

Prototype Main Process: SLA, SLS, CNC, PJP

Product advantages:

1.Customer’s design and logo;

2.Small order acceptable;

3.Free sample for plastic ;

4.100% raw material used;

5.A variety of materials to choose;

6.High precision&high quality control;

7.Competitive prices;

8.Safe packing & prompt delivery.

Send your message to us:

-

Good Quality China Factory Silicone Rubber Cust...

-

High definition China Clear Rubber Stopper Bead

-

OEM Manufacturer China Rubber Seal Plug for Aut...

-

PriceList for China Food Grade Sanitary Tri-Cla...

-

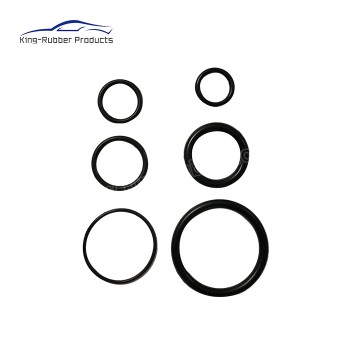

OEM China Factory wholesale oring rubber seal ...

-

Bottom price China Automotive EPDM Hose/EPDM Ru...